This is Part 2 of a great article on LED lights by our good friend and genius tech guy, Michael Blake at Palladium Technologies.

What Constitutes A Good LED Fixture

In my previous article I discussed the Facts and Myths of LED lights, which brings us to the stage of revealing the magic to selecting the correct fixtures. I use the word magic only because there seems to be so much confusion regarding what constitutes a good LED fixture, it must be either luck or magic when there is a successful implementation of LED lights. Much of my discussion will center on the traditional down light of which hundreds can be found on our today’s yachts. These can be used for general illumination, lighting specific artwork on the yacht, or special purposes, such as night illumination on the bridge. I will now unveil those items from my magic cape, which I feel are critical to achieving an acceptable, LED upgrade or new build installation. For ease of comprehension, I have broken these items into categories, in general order of importance, but as you will read all can be quite important.

Heat Management

This is an item that I discussed in my previous article, which I will reiterate here. LED’s do generate heat, and this heat must be removed in a different manner than the traditional Halogen bulb. As we found in my previous article, the heat that is generated by the LED is 70% of the total energy consumed, and is generally removed with heat sinks installed on the back of the fixture. I like to examine these heat sinks for quality and quantity, which translates directly to the longevity of the LED fixture.

Lumens

Is simply a unit of measure for the amount of visible light emitted from a source. Technically this relates back to a candela (candle), where the common candle emits light with a luminous intensity of roughly one candela. One lumen (lm) is equal to the light of one candela (candle) emitted in 1 square meter.

Now let’s look at the comparison of lumens with a standard halogen 20-watt light outputting approximately 235 lm of light. Replacing this 20-watt halogen with a LED requires careful selection based upon the lumens and not the wattage. Some LED fixtures are more efficient than others, thus for the same wattage, more lumens are produced.

CCT – Correlated Color Temperature

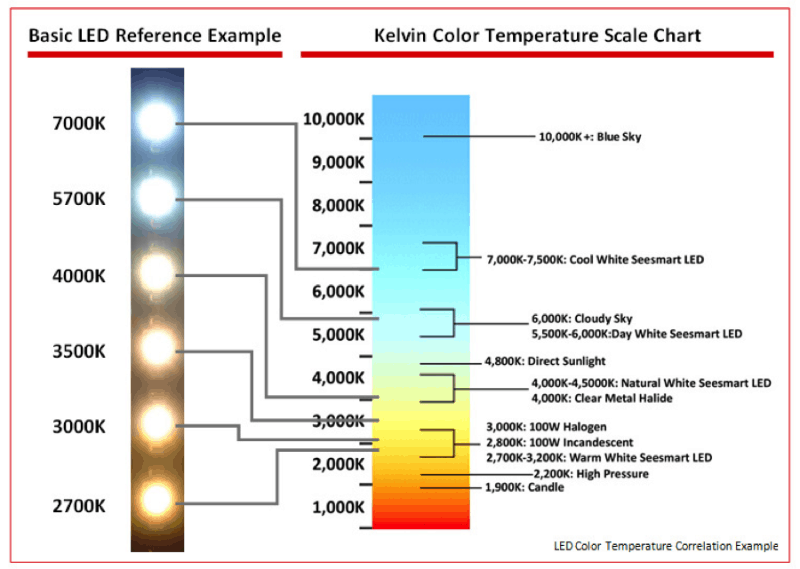

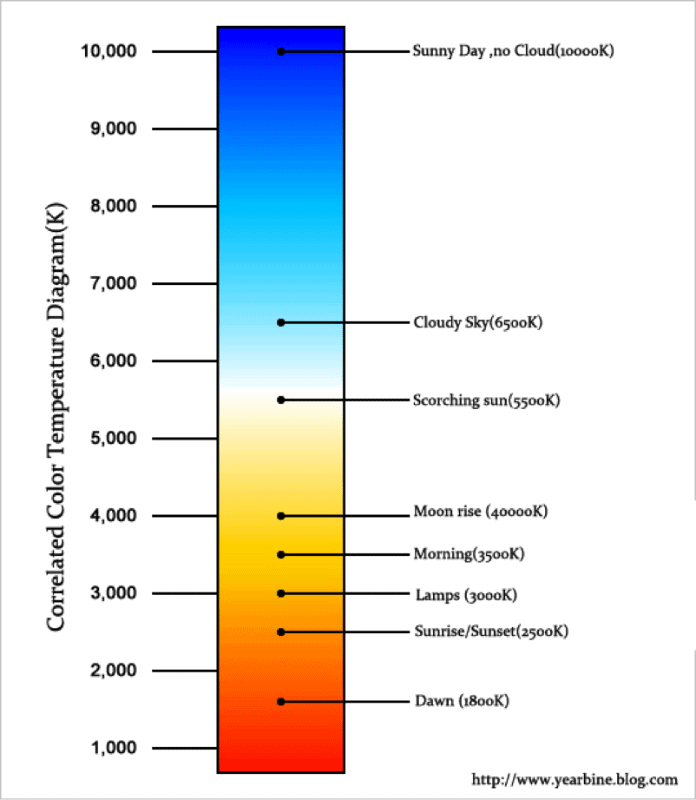

CCT is a scale, which measures the light produced by a fixture to the visible light spectrum in degrees kelvin (K). I believe this to be one of the more important parameters in selecting LED lights, and must be fine-tuned to the area being lit and the desired expectations. As humans we are affected by CCT, and here are some examples.

Moods Associated with CCT

- 3000K or less will make people feel warm and cautious.

- 2000-5000K will make us to feel cool, and it is the type of white light, which gives us a brisk mood and is normally found in stores, hospitals, offices, restaurants, and waiting rooms.

- 5000-6500k is a bit blue and is found in offices, meeting rooms, and classrooms, providing us with the focus for concentrated work. This color temperature is considered a cold light.

At right are two charts that help bring this CCT into daily reference.

Our lighting designers at Palladium will typically use the warmer temperatures (2800-3500k) in the owner and guest areas, while in the galley and engine rooms we will use LED fixtures in the 4500-6500K ranges.

A key to selecting the correct CCT or color temperatures is to also make sure the manufacture of the LED fixtures can provide the assurance that all LED fixtures selected for same 3000K will truly be 3000K with a very small variance. Otherwise, it can be disturbing to have different CCTs in the same area.

CRI – Color Rendering Index

CRI is a measure used to represent how effective a light source is at showing objects colors “realistically” or “naturally” in reference to either incandescent light or daylight. Essentially it is the light sources ability to accurately render all frequencies of its visible color spectrum.

Using a scale of 1-100, with 100 to be a full representation of all the colors, and 1 being a total lack of color representation, we can now compare our LED fixtures.

When applying this to a yacht, imagine an interior designer choosing exquisite fabrics, woods and stones attempting to bring to life the yacht’s interior for an owner only to find that the LEDs installed have a CRI of 70. We defeat and mute the vision of the designer. Since most refits replace exiting tungsten-halogen lamps with a CRI of 100, it would then be important for us to achieve a high CRI with the LED replacements, or the owner and guests will note distinct differences.

Optics

Another important selection criteria is the optics of the LED light fixture. When you look up at the LED light, do you see multiple LED pinpoints, or is there a pleasant diffused light being emitted by the fixture. In a quality LED light, much engineering is applied to presenting the lumens of light, in a diffused fashion, which is less harsh on the eye, than the multiple LED pinpoints.

Along with the optics is the selection of the correct angle that the reflector is engineered for. This could be more of a direct spotlight with a 30-degree angle or up to 100 degrees for flood lighting.

Dimming and LED Drivers

This is one area of an LED fixture that I could probably write an entire chapter on, much of it from real experience on yachts, coupled with our lab testing at Palladium.

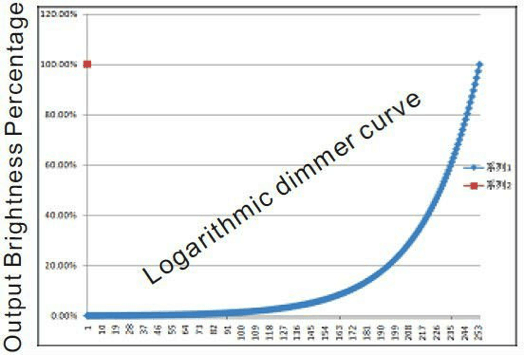

First let me bring all of us back to the elementary structure of an LED, which is a Light Emitting Diode. From an electrical engineering standpoint, this is a semiconductor, which like all other diodes is a current driven device. Actual operating voltages vary from 1.8 to 3.4 volts DC for normal operation. Unlike our incandestant or halogen lights, where changing the voltage results in a linear effect on the light output, LEDs are non-linear (see chart below) when dimmed and are basically a current device. If we dim by varying the current to the LED, then we have the potential to also change the CCT or color temperature of the fixture, which would be unacceptable.

LED Dimming

So you may ask why bring electronics in this discussion? It is because controlling LED lights is much more complex that incandescent or halogen lights. The LED driver must be sophisticated and matched to the LED installed so that they work in unison, using techniques such as PWM (pulse width modulation), leading edge or trailing edge trimming of the voltage waveform. In addition, since an LED operates on low voltage DC, this driver must reduce the voltage to that level, while also in many cases convert from AC to DC.

Now just to complicate this a bit more, not all LEDs are created equal, thus actual dimming level may not be achieve from one fixture to another.

The end result of not having a properly engineered LED lighting system is the dreaded flicker. Studies have shown that the human eye can detect visible flicker at frequencies below 100 Hz or 100 times per second. The negative physiological effects of flicker are headaches, migraines, eyestrain, distraction, and in severe cases epileptic seizures. This last item was of great concern to one of our customers who had epileptic seizures, which were triggered by flicker or strobing.

Another item, which is most disturbing in a poorly engineered LED dimming system, is “pop-on” and “pop-off”. As noted earlier LED’s are not linear in their dimming, and there comes a point at around 23% that the LED can suddenly go off (pop-off). When we try to turn this LED back on, by using the dimming control, we will get to that 23% level, and suddenly the light comes back on, which is our “pop-on”.

In summary, there are three electronic components that must be engineered and matched for a smoothly operating LED system, and they are; LED dimmer, LED driver and the LED fixture.

Aesthetics

I would be remiss if I did not mention the aesthetics as an important item in the selection of the correct LED fixture. What is the quality of the materials used in the construction and presentation of the fixture and are they marine grade? Can the bezels be custom matched to the headliner or fabrics? Unless the fixture is to be a conversation piece, it should blend into its surroundings and not call attention to that area where the light is being emitting.

Strip Lights

Most everything already discussed in this article also applies to strip lights. Heat is an issue, and if you are going to use high bright LED strip lights, then heat sinks are must. We had one lighting design project were the owner wanted all indirect lighting, which we simulated with very high bright LED strip lights. For this installation we designed long aluminum heat sinks with proper ventilation to remove the heat. Without these heat sinks the LEDs would de-solder themselves from the strip circuit board and fail.

To me, when LED strip lights are installed on a yacht in such a way that you actually see all of the individual “hot spots” of light for each LED on the strip, it becomes self defeating. The use of proper diffusers will provide an even glow of light, without calling the attention to this indirect lighting.

Special Purpose LEDs

One of the great features of using LEDs is that manufacturers can build multi color lighting fixtures. One of our more recent lighting projects at Palladium; we used a tri-color LED fixture, to provide either white, red or blue lighting on the bridge. White was for daytime or while at the dock, red for night navigation and blue for entertaining, or a cooler effect.

Compliance to Standards

We should check carefully if the LED fixtures and equipment that we select for our yachts has the certifications and electrical compliances. Emitting stray RF energy or low frequencies on our power circuits, could translate into a safety issue for the navigation equipment onboard.

In summary, we have had great success with our LED projects at Palladium, but it does take a lot more attention to the details as discussed above, along with proper electrical engineering. The end result can be an elegant lighting system, with lower energy usage.